Introduction

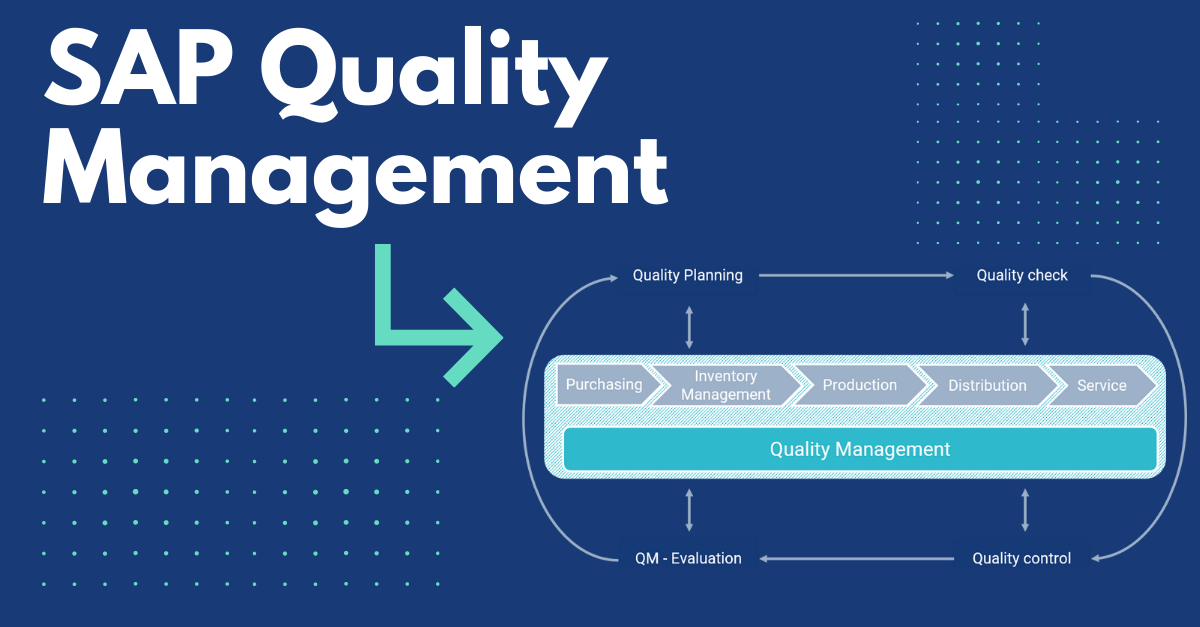

SAP Quality Management is a comprehensive module within the SAP ERP system designed to ensure quality control and compliance throughout an organization’s processes. It enables businesses to maintain high-quality standards in procurement, production, and delivery by integrating quality management with other SAP modules like MM, PP, and SD. Refer to the SAP Training in Noida to learn more about SAP QM. With features like quality planning, inspection, and audit management, SAP QM helps minimize defects, ensure compliance, and enhance customer satisfaction, making it a vital tool for operational excellence.

What Is SAP Quality Management?

SAP QM (Quality Management) is an integral module of the SAP ERP system designed to ensure the quality of products and processes within an organization. It enables businesses to implement robust quality management practices, ensuring compliance with industry standards and regulatory requirements.

The module supports various quality-related activities, such as quality planning, quality inspection, and quality control. It helps manage quality at different production and procurement stages, from raw material inspection to final product delivery.

Key features of SAP QM include:

- Quality Planning: Creation of inspection plans, material specifications, and sampling procedures.

- Quality Inspection: Execution of inspections at different points, such as goods receipt, production, or before delivery.

- Quality Control: Monitoring and analysing inspection results to identify and resolve quality issues.

- Audit Management: Conducting internal and external quality audits to maintain standards.

- Integration: Seamless integration with modules like SAP MM (Materials Management), SAP PP (Production Planning), and SAP SD (Sales and Distribution).

SAP QM improves product quality and reduces wastage and non-compliance risks, ultimately enhancing customer satisfaction and operational efficiency. It is a crucial tool for organizations that maintain high-quality standards and achieve competitive advantages.

Key Functions Of SAP Quality Management:

SAP QM offers a comprehensive set of tools and functionalities to ensure high-quality standards in all phases of the production and procurement lifecycle.

Below are the primary functions of SAP QM:

1. Quality Planning

This involves defining quality standards and creating inspection criteria for materials and processes.

- Inspection Plans: Define the inspection methods, characteristics, and sampling procedures.

- Quality Info Records: Specify quality-related agreements with vendors.

- Master Data Integration: Link inspection plans with material master and work centres.

2. Quality Inspection

SAP QM facilitates systematic inspections to maintain quality at every stage.

- Incoming Goods Inspection: Evaluate raw materials and components upon receipt from vendors.

- In-Process Inspection: Monitor production processes to detect and correct deviations early.

- Final Product Inspection: Ensure that finished goods meet quality specifications before delivery.

- Defect Recording: Capture and classify defects with detailed descriptions and root causes.

3. Quality Control

This function focuses on controlling and optimizing processes to meet quality objectives.

- Control Charts: Monitor processes and identify trends or variations.

- Statistical Process Control (SPC): Analyse inspection data to maintain process efficiency.

- Corrective and Preventive Actions (CAPA): Address recurring issues to prevent future defects.

4. Quality Notifications

Quality notifications help manage and track quality issues efficiently. Aspiring SAP professionals can join the SAP Course in Delhi to learn more about SAP QM Quality Notifications.

- Complaint Handling: Record and resolve customer complaints.

- Internal Issues: Report and address quality problems within the organization.

- Vendor Issues: Manage and resolve quality problems with suppliers.

5. Audit Management

SAP QM supports the planning and execution of quality audits.

- Internal Audits: Assess compliance with internal standards and procedures.

- Vendor Audits: Evaluate supplier performance and adherence to quality agreements.

6. Integration with Other Modules

SAP QM seamlessly integrates with modules like:

- SAP MM: Quality checks during procurement.

- SAP PP: In-process quality control during manufacturing.

- SAP SD: Ensuring product quality before shipping.

7. Quality Certificates

Generate certificates of compliance or analysis for products to assure customers of their quality.

8. Reporting and Analytics

SAP Quality Management provides detailed reports and dashboards for decision-making, helping to monitor quality performance and identify areas for improvement.

Thus, getting one of the SAP Certifications on SAP QM can be a wise career move for aspiring professionals. SAP QM empowers businesses to enforce stringent quality standards, reduce defects, and enhance customer satisfaction. Its integration with other SAP modules ensures streamlined processes and a comprehensive approach to quality management.

Conclusion

To sum up, SAP Quality Management is a powerful module that ensures product and process quality across procurement, production, and delivery. Its key functions—quality planning, inspection, control, notifications, and audit management—streamline quality assurance while integrating seamlessly with other SAP modules. By reducing defects, optimizing processes, and enhancing compliance, SAP QM helps organizations achieve operational excellence and boost customer satisfaction, making it an essential tool for maintaining competitive advantage in today’s quality-focused market.