Boilers are critical components in many industrial and residential heating systems. They rely on various components to function effectively, and one such crucial part is the boiler gasket. This guide will delve into the types of boiler gaskets, their functions, and essential maintenance tips to ensure optimal performance and longevity.

What is a Boiler Gasket?

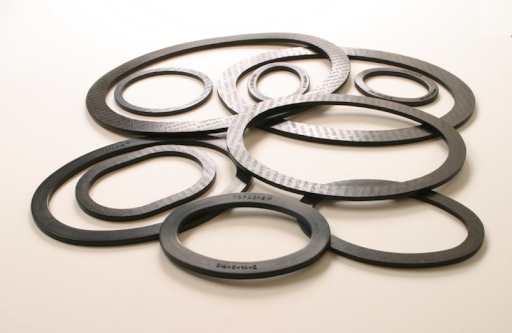

A boiler gasket is a sealing component used to prevent leaks between different parts of a boiler. It plays a vital role in maintaining the pressure and temperature within the system, ensuring safe and efficient operation. Gaskets are typically placed between joints, flanges, or other mating surfaces in the boiler to create a tight seal.

Types of Boiler Gaskets

Understanding the different types of boiler gaskets is crucial for selecting the right one for your system. Here are the most common types:

1. Graphite Gaskets

Graphite gaskets are known for their excellent thermal conductivity and resistance to high temperatures. They are often used in high-temperature applications where other materials might fail. Graphite gaskets can withstand extreme temperatures and pressures, making them suitable for industrial boilers and high-pressure steam systems.

2. Metal Gaskets

Metal gaskets are made from various metals, including copper, steel, and stainless steel. They are designed to provide a strong seal in high-pressure and high-temperature environments. Metal gaskets are durable and can handle significant stress without deforming. They are commonly used in applications requiring high strength and resistance to harsh conditions.

3. Non-Asbestos Gaskets

Historically, asbestos was used in gaskets due to its heat resistance. However, due to health concerns, non-asbestos alternatives have become the standard. These gaskets are made from aramid fibers or graphite mixed with other compounds. They offer similar heat resistance and sealing capabilities without the risks associated with asbestos.

4. Rubber Gaskets

Rubber gaskets are versatile and can be used in a range of applications. They are flexible and seal well when vibrations or minor movements occur. Compared to graphite or metal gaskets, rubber gaskets are typically used in lower-temperature and pressure applications.

Functions of Boiler Gaskets

Boiler gaskets perform several critical functions in maintaining the efficiency and safety of a boiler system:

1. Sealing

The primary function of a boiler gasket is to create a tight seal between two surfaces to prevent leaks of steam, water, or other fluids. This is crucial for maintaining the pressure within the system and ensuring that the boiler operates efficiently.

2. Preventing Contamination

Gaskets help prevent contaminants from entering the boiler system. By creating a seal, they ensure that external substances do not interfere with the operation of the boiler, which can otherwise lead to system failures or reduced efficiency.

3. Maintaining Pressure

Boilers operate under high pressure, and gaskets are essential in maintaining this pressure. A well-sealed gasket prevents pressure from escaping and ensures the boiler operates within its designed parameters.

4. Reducing Vibration

In some cases, gaskets can also help absorb vibrations between boiler components. This reduces wear and tear on the system and contributes to the overall longevity of the boiler.

Maintenance Tips for Boiler Gaskets

Proper maintenance of boiler gaskets is essential for ensuring the longevity and efficiency of your boiler system. Here are some key tips:

1. Regular Inspections

Regular inspections are crucial for identifying signs of wear or damage. Check gaskets for any visible signs of deterioration, such as cracking, swelling, or compression. Regular inspections help catch issues early, preventing potential leaks or system failures.

2. Proper Installation

Ensure that gaskets are installed correctly to avoid leaks. Follow the manufacturer’s guidelines for installation, including proper torque settings for bolts and correct alignment of components. Incorrect installation can lead to premature gasket failure and reduced system efficiency.

3. Avoid Over-Tightening

While ensuring a tight seal is essential, over-tightening bolts can damage the gasket material and lead to leaks. Use a torque wrench to apply the correct amount of pressure and avoid damaging the gasket.

4. Monitor System Pressure and Temperature

Regularly monitor the pressure and temperature of your boiler system. Abnormal pressure or temperature readings can indicate issues with the gasket or other components. Address any irregularities promptly to prevent damage.

5. Replace Worn Gaskets Promptly

If you notice any signs of gasket wear or failure, replace the gasket as soon as possible. Using a damaged gasket can lead to leaks, reduced efficiency, and potential damage to other boiler components.

6. Use Compatible Gaskets

Ensure that you use the correct type of gasket for your specific boiler and application. Using incompatible gaskets can lead to poor sealing performance and potential system failures. Consult a professional if you are unsure about the right gasket for your system.

Conclusion

Understanding the different types of boiler gaskets, their functions, and maintenance requirements is crucial for your boiler system’s efficient and safe operation. By selecting the appropriate gasket and following proper maintenance practices, you can ensure that your boiler operates effectively and lasts longer. Regular inspections and prompt replacement of worn gaskets will help maintain your boiler’s performance and reliability, ensuring it continues to operate smoothly and efficiently.

By considering these considerations, you can enhance the longevity and efficiency of your boiler system, prevent costly repairs, and ensure optimal performance.