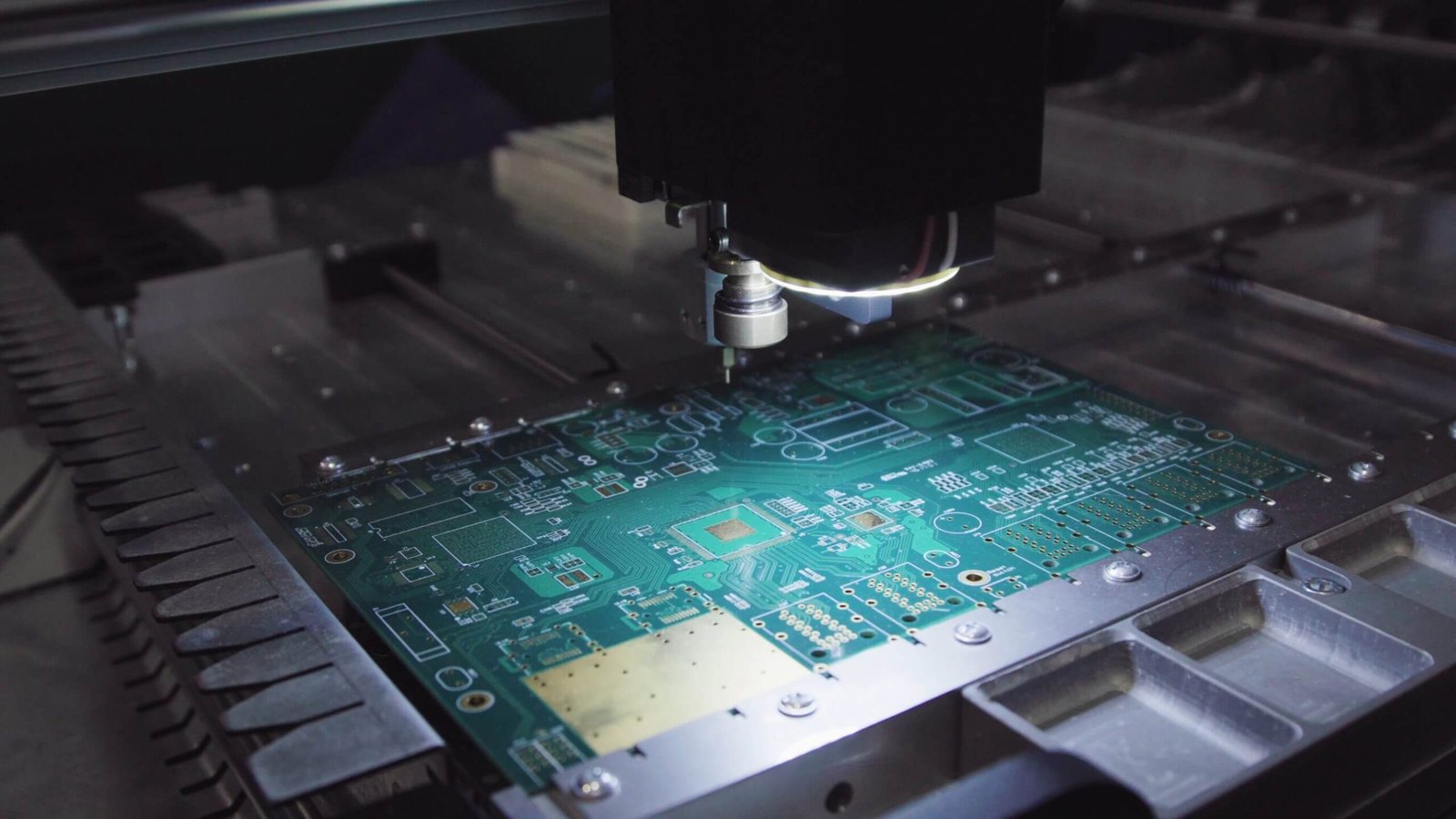

PCB assembly or PCBA is a process where the PCB is made using a variety of materials and components. The board is then assembled with other parts such as connectors, latching mechanisms, and even LEDs. The process is completely automated to ensure that every component fits perfectly together without any errors.

The PCB assembly process is a complex one. There are many different types of PCB assemblies, each requiring its own unique set of skills and knowledge to perform correctly.

If you want to get into the world of PCB assembly, you need to know what you’re getting into and how to perform it successfully.

What are the steps of PCBA?

Printed circuit board assembly is the process of connecting printed circuit boards together in order to assemble a complete product.

The first step in the process is pre-assembly. This involves taking all of your parts and putting them onto the board in preparation for soldering: placing resistors, capacitors, diodes, transistors, etc., on their appropriate pads or traces. It also involves placing any ICs or other integrated circuits onto their specific pads on the board as well as mounting any other components such as connectors or LEDs onto their respective places on the board.

The steps of the assembly are:

- PCB layout, where a technician determines the size, shape, and placement of the components on the PCB

- Assembly, where engineers solder or glue components to their PCB

- Testing, where technicians test the assembled product for functionality.

SMT & Thru-hole assembly method:

Through-hole assembly is a method of fabricating printed circuit boards that uses a board with holes in it. This type of PCB is known as a through-hole assembly. Through hole is a term used to describe the process of drilling or cutting out electronic components from a flat, flexible material. The main advantage of through-hole assembly is that it makes PCBs used in components that undergo high voltage and tougher environment conditions such as a transformer.

Surface mount technology refers to an electronic device that has a large number of integrated circuit chips on its surface rather than buried within it. Surface mount technology has been around since the 1960s but was only recently popularized by the microprocessor industry. The relatively high cost and difficulty of soldering these chips onto their surfaces have led to the use of surface mount technology instead.

The main difference between surface mount technology and through-hole PCB assembly is the method of soldering. Surface mount technology requires that all of the components be mounted on a single plane, or surface. Through-hole PCB assembly uses a special type of solder that is inserted into holes drilled in the board to make connections between the components.

The advantage of surface mount technology is that it allows for quicker, more efficient production cycles. This is because there are no soldering operations required for each individual connection, which makes it possible for manufacturers to produce boards at a faster pace than through-hole design would allow.

How to select the right company?

A PCB assembly company is one of the most important elements in a product development process. It can help you ensure that your products are produced on time, and with minimal errors. Here are some tips to help you choose the right PCBA company:

- Do your research first

Before you decide on an assembly company, do some research. Find out how many years they have been in business, what kind of experience they have, and what kind of reputation they have had with their customers. Check out their website and social media profiles as well. You should also ask them about their quality assurance program and how it works. This will give you an idea about whether or not the company has experience working with your type of product or not.

- Ask for references

Once you have found a few potential candidates for your project, ask them for at least three references from previous customers that worked with them on similar projects in the past. You may also want to ask them if they have any specific types of customers that they prefer working with or not working with at all.

- Certification

Make sure that the manufacturer of your parts has been certified by ICC and RoHS (Restriction of Hazardous Substances), which means they have met all safety standards set by these organizations. This will make it easier for you when it comes time to install them on your PCBs as well as provide legal protection if there are any issues with their installation or use in the future. These certifications also mean that every part used on your boards is guaranteed to work properly together and will not cause any damage.

- Pricing

Go through the websites and check the pricing pages of different companies so as to get an idea of the standard market prices.