Helium leak detectors play a crucial role in various manufacturing processes. They ensure quality control and enhance product reliability. This article explores the benefits of using helium leak detectors in manufacturing. By understanding these advantages, manufacturers can make informed decisions that impact their operations positively.

What Are Helium Leak Detectors?

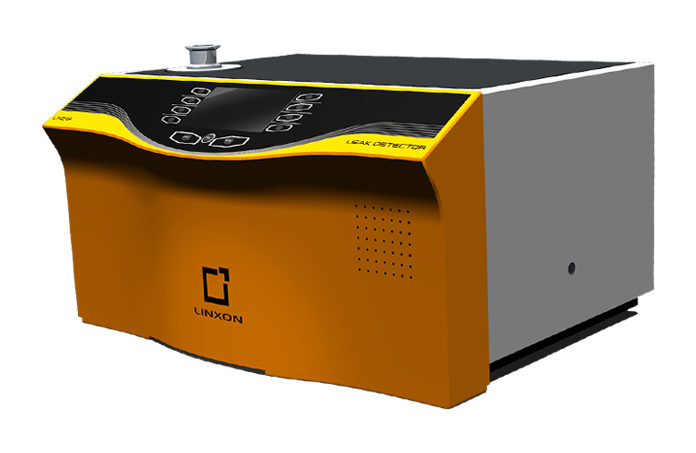

Specialized devices called helium leak detectors are made to find and measure leaks in a variety of settings. Because of its special characteristics, they use helium as a tracer gas. Because helium is tiny, diffuses rapidly, and is inert, it is perfect for leak detection. These detector aid in ensuring the performance and integrity of the product throughout manufacture. Helium leak detectors are essential instruments for quality control in the automotive, aerospace, and electronics industries.

Enhanced Product Quality

A major advantage of helium leak detector is improved product quality. In the manufacturing industry, even a small leak can cause serious problems. Leaks, for instance, can impact fuel economy and engine performance in the automotive sector. Similar to this, tiny leaks in the electronics industry can lead to component failures. Manufacturers can find and fix these leaks early in the production process by using helium leak detectors. By being proactive, the possibility of expensive recalls is decreased and products are guaranteed to fulfill quality standards.

Increased Efficiency

Effectiveness is essential in every manufacturing setting. Helium leak detector contribute to increased efficiency by optimizing the production process. Conventional leak detection techniques can be labor- and time-intensive. Helium leak detectors, on the other hand, offer precise and quick findings. This speed reduces downtime by enabling manufacturers to promptly detect and fix leaks. Consequently, production lines remain functioning, leading to enhanced overall efficiency.

Cost-Effective Solution

For manufacturers, installing helium leak detectors can be an affordable solution. Although there can be upfront investment costs, these are outweighed in the long run by the advantages. Early leak detection and repair can significantly reduce the expense of product recalls and failures. Utilizing helium leak detector also contributes to a decrease in waste and rework. Manufacturers can prevent further expenses later on by making sure that their products are leak-free from the beginning. Helium leak detector are therefore a wise purchase for any manufacturing facility.

Compliance with Industry Standards

Manufacturers have to abide by a number of rules and industry norms. Companies can successfully achieve these criteria with the aid of helium leak detectors. There are tight regulations governing product integrity in many businesses, including the aerospace and pharmaceutical industries. Products are guaranteed to meet these requirements by using helium leak detector, which lowers the possibility of non-compliance fines. Additionally, demonstrating compliance can boost a company’s brand and increase customer trust. In markets with intense competition, where product quality is crucial, this trust is priceless.

Versatility across Industries

The adaptability of helium leak detectors to various sectors is another benefit. Numerous industries, including automotive, aerospace, electronics, and pharmaceuticals, use these detectors. Helium leak detector are used in the automotive industry to guarantee that fuel systems are leak-free. They support the integrity of pressurized systems in aircraft. These detectors are critical to the testing of vacuum seals in delicate electronics components. Helium leak detector are a useful instrument for a variety of sectors due to their adaptability to various manufacturing settings.

Easy to Use

The ease of use of helium leak detectors is a design feature. A lot of models have intuitive user interfaces that make it easy for operators to comprehend and interpret outcomes. Employee training on the operation of these detectors is frequently simple. Because of its simplicity, there is less of a learning curve and leak detection may be easily included into the production process. Because of this, manufacturers may take advantage of helium leak detector accuracy without needing specialized training or technological know-how.

Improved Safety

In any manufacturing setting, safety comes first. Leak detectors for helium improve safety by spotting possible threats. Leaks in pressure vessels or gas lines, for instance, can result in hazardous circumstances. Manufacturers can prevent mishaps by taking corrective action as soon as these leaks are discovered. This proactive approach protects organizational assets in addition to employees. Furthermore, fostering a safe workplace can raise productivity and morale among staff members.

Real-Time Monitoring Capabilities

Current helium leak detectors are capable of monitoring in real time. Manufacturers are now able to continuously monitor leak detection throughout production thanks to this technology. Real-time data gives producers insightful information about how their products are made, empowering them to take well-informed decisions. For instance, quick action can be done to fix the issue if a leak is found. This degree of observation guarantees that goods stay within designated tolerances and improves overall quality control.