Patient safety is the top priority in healthcare. Sterile packaging of medical devices, instruments, and supplies goes a long way in ensuring this kind of safety. This type of packaging prevents contamination and maintains the sterility of products until they are ready for use. Essential in minimizing the risk of infections and ensuring the effectiveness of medical procedures, sterile packaging plays a vital role in safeguarding patient health to the maximum possible extent, something which this article aims to highlight.

Protecting Against Contamination

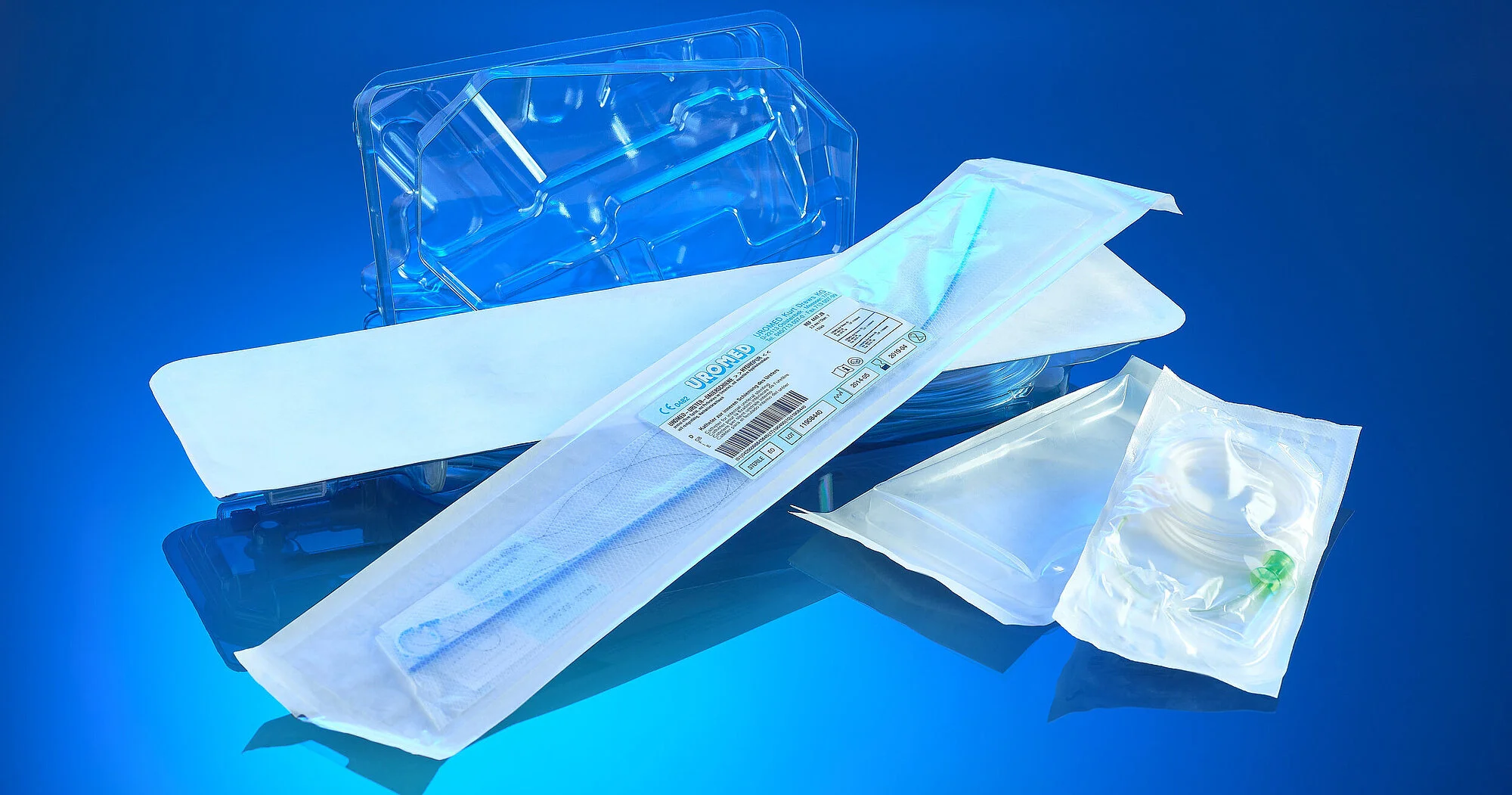

The primary purpose of sterile packaging is to protect medical products from contamination by bacteria, viruses, and other harmful microorganisms. During manufacturing, medical devices and supplies are sterilized to remove any contaminants. Without proper packaging, these sterile conditions can easily be compromised before the products reach the patient. Such packaging acts as a barrier, preventing any harmful substance from contacting the medical product. This protection prevents infections during surgeries, treatments, and routine medical procedures. Without this kind of packaging, the risk of contamination would be significantly higher, endangering patient safety.

Ensuring Product Sterility During Transportation

Medical products often need to travel long distances before reaching healthcare facilities. During transportation, these products can be exposed to various environmental factors, such as dust, moisture, and physical impact, that could compromise their sterility. Sterile packaging protects products from these external threats, ensuring their safety and readiness for use. The packaging materials are carefully selected to withstand the rigors of transportation while maintaining the integrity of the product inside. This ensures that healthcare providers receive medical supplies in perfect condition, ready to be used safely on patients.

Meeting Industry Standards and Regulations

The medical industry is subject to strict regulations to ensure that products meet safety and quality standards. Sterile packaging is a critical component in complying with these regulations. Various regulatory bodies, such as the FDA and ISO, have established guidelines for sterile packaging to ensure that it meets the necessary safety requirements.

Manufacturers are required to use packaging materials that are tested and approved for maintaining sterility. Following these guidelines is essential for preventing product recalls and ensuring the highest standards in patient safety. Proper sterile packaging helps healthcare providers trust that the medical devices and supplies they use are safe and reliable.

Enhancing Patient Confidence

When patients undergo medical procedures, they trust that healthcare providers are using safe and sterile instruments. Sterile packaging plays a crucial role in building this trust. Patients are more confident knowing that the medical products used during their treatments are protected from contamination. In addition, healthcare providers can focus on delivering the best care without worrying about the safety of the products they use. This form of packaging ensures that medical devices and supplies remain safe from the point of manufacture to their final use in patient care.

Conclusion

Sterile packaging is essential in the healthcare industry for ensuring patient safety. By protecting medical products from contamination, maintaining sterility during transportation, and meeting regulatory standards, this type of packaging plays a vital role in safeguarding health. The use of proper packaging helps reduce the risk of infections and enhances trust between patients and healthcare providers. As medical technology continues to advance, such packaging will remain a key factor in ensuring that patients receive the highest standard of care.