Introduction

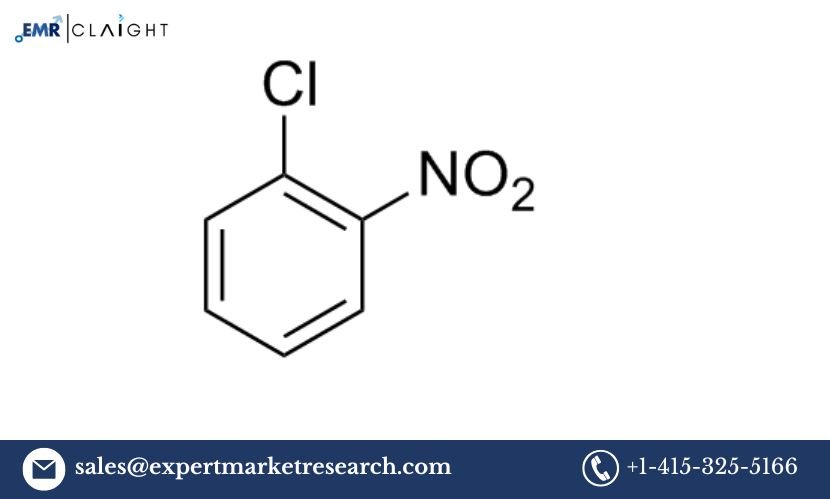

Ortho Nitro Chloro Benzene (ONCB) is an essential chemical intermediate used in the production of various industrial chemicals, including agricultural pesticides, dyes, and pharmaceuticals. It is a key compound in the production of other valuable chemicals, such as 2,4-dichloroaniline, which is widely used in the manufacturing of herbicides. The growing demand for ONCB in sectors like agriculture, pharmaceuticals, and textiles makes it a valuable product for chemical manufacturers. This Ortho Nitro Chloro Benzene Manufacturing Plant Project Report provides a detailed analysis of the process of setting up a manufacturing facility for ONCB. It covers aspects such as raw materials, production processes, machinery requirements, market potential, financial planning, and environmental considerations. The report is designed to guide potential investors, entrepreneurs, and manufacturers in setting up a successful ONCB manufacturing plant.

Market Overview of Ortho Nitro Chloro Benzene

Ortho Nitro Chloro Benzene is primarily used in the synthesis of agrochemicals, dyes, and pharmaceuticals. The global demand for ONCB has grown steadily due to the increasing need for agricultural chemicals, the expansion of the pharmaceutical sector, and the rising use of synthetic dyes in the textile industry. As a crucial intermediate in the production of pesticides, ONCB is integral to the agricultural industry, which remains one of the largest consumers of this compound.

Key Market Drivers:

- Growing Agricultural Sector: The increasing demand for pesticides and herbicides to enhance agricultural productivity drives the demand for ONCB as an intermediate.

- Pharmaceutical and Chemical Industry Demand: ONCB is used in the synthesis of various chemicals used in pharmaceutical formulations, making it critical for the pharmaceutical industry.

- Rising Textile and Dye Industries: The textile industry requires ONCB for the production of synthetic dyes used in fabric manufacturing, driving its demand in the textile sector.

- Increased Focus on Sustainable Agriculture: As the agricultural sector shifts towards more efficient and eco-friendly solutions, the demand for high-quality pesticides and herbicides continues to rise.

Get a Free Sample Report with Table of Contents@

Raw Materials for Ortho Nitro Chloro Benzene Manufacturing

The production of Ortho Nitro Chloro Benzene requires specific raw materials that contribute to its chemical properties and production efficiency. These materials include:

Key Raw Materials:

- Chlorobenzene: This is the primary starting material used in the production of ONCB. It undergoes nitration and chlorination to form Ortho Nitro Chloro Benzene.

- Nitric Acid: Used for the nitration process, where the nitro group (-NO2) is introduced to the benzene ring.

- Hydrochloric Acid: Used in the chlorination process to introduce the chlorine atom (-Cl) to the benzene ring.

- Catalysts: Various catalysts may be used to enhance the reaction rates during the nitration and chlorination processes.

- Solvents: Organic solvents, such as acetone or toluene, may be used during the synthesis process to facilitate the reactions and purify the product.

Manufacturing Process of Ortho Nitro Chloro Benzene

The production of Ortho Nitro Chloro Benzene involves a series of chemical reactions, including nitration and chlorination. The process must be carefully controlled to ensure the desired quality and yield of the product. Below is a breakdown of the main steps in the production process:

1. Nitration of Chlorobenzene

The production process begins with the nitration of chlorobenzene. In this step, chlorobenzene is mixed with concentrated nitric acid (HNO3) under controlled conditions. The reaction introduces a nitro group (-NO2) into the benzene ring. The process is exothermic, and the reaction temperature must be carefully regulated to avoid unwanted side reactions.

This reaction forms Ortho Nitro Chloro Benzene as the primary product, along with some by-products. The reaction mixture is cooled and then neutralized to separate the product from the acids.

2. Chlorination

The second step in the production process is the chlorination of the nitrated compound to introduce the chlorine atom into the molecule. This process is typically carried out by mixing the nitrated product with hydrochloric acid (HCl) and chlorine gas (Cl2). The chlorination step must be carefully controlled to avoid over-chlorination and ensure that the chlorine atom is introduced in the correct position on the benzene ring (in the ortho position relative to the nitro group).

This process results in the formation of Ortho Nitro Chloro Benzene, with chlorine atoms positioned ortho to the nitro group.

3. Purification and Isolation

After the nitration and chlorination reactions, the product is typically a mixture of various compounds, including impurities and unreacted starting materials. The next step involves purifying the product to isolate Ortho Nitro Chloro Benzene. This may be achieved through a combination of solvent extraction, distillation, and filtration.

4. Drying and Packaging

The final purified Ortho Nitro Chloro Benzene is dried to remove any residual solvents or moisture. The product is then packaged into appropriate containers for distribution to customers, such as chemical manufacturers, pesticide producers, and textile companies.

Machinery and Equipment for Ortho Nitro Chloro Benzene Production

Setting up a manufacturing plant for Ortho Nitro Chloro Benzene requires specialized machinery and equipment to handle the chemical reactions and ensure the quality and efficiency of production. The following equipment is typically required:

- Reaction Vessels: Large stainless steel or glass-lined vessels to carry out the nitration and chlorination reactions.

- Heat Exchangers: Used to control the temperature during exothermic reactions and maintain optimal reaction conditions.

- Filtration Units: Used to remove impurities from the reaction mixture and ensure that the final product is pure.

- Distillation Units: For separating the product from solvents and other by-products.

- Drying Equipment: To remove any residual solvents or moisture from the final product.

- Packaging Machines: For packaging the finished product into suitable containers for shipment.

Regulatory Compliance and Certifications

Ortho Nitro Chloro Benzene manufacturing facilities must comply with various local and international regulatory standards. These regulations ensure that the production processes are safe, environmentally friendly, and in line with industry standards. Key certifications and compliance requirements include:

- ISO 9001 Certification: Ensures that the plant follows high standards of quality management throughout the production process.

- ISO 14001 Certification: Focuses on environmental management practices to minimize the environmental impact of the manufacturing facility.

- RoHS Compliance: Ensures that the production process complies with regulations regarding the restriction of hazardous substances in chemicals.

- OSHA Regulations: Ensures that the plant complies with occupational safety standards to protect workers from hazards associated with the chemical production process.

Financial Planning and Investment

Setting up an Ortho Nitro Chloro Benzene manufacturing plant requires a significant financial investment. The investment includes costs for land acquisition, building construction, machinery purchase, raw material procurement, and operational expenses. Below are the key financial components to consider:

- Initial Investment: The initial investment will cover costs related to plant construction, machinery installation, and raw material procurement.

- Operating Costs: These include expenses such as labor, energy, raw materials, maintenance, and overhead costs.

- Revenue Generation: The revenue from the plant will primarily come from the sale of Ortho Nitro Chloro Benzene to chemical manufacturers, pesticide producers, and textile companies.

- Profitability Analysis: A detailed profitability analysis should be conducted, considering factors such as production costs, pricing strategies, and market demand.

Workforce Requirements

A skilled workforce is essential to ensure the efficient operation of the Ortho Nitro Chloro Benzene manufacturing plant. Key personnel include:

- Chemical Engineers: To design, optimize, and monitor the chemical processes.

- Production Workers: For operating machinery, handling raw materials, and overseeing the production process.

- Quality Control Inspectors: To test the final product and ensure that it meets the required specifications.

- Maintenance Technicians: To maintain machinery and ensure smooth operations.

- Sales and Marketing Team: For promoting and selling the final product to customers.

- Environmental Health and Safety Officers: To ensure that the plant operates in compliance with safety and environmental regulations.

Environmental Considerations

The manufacturing of Ortho Nitro Chloro Benzene involves the use of hazardous chemicals and processes that could have a significant environmental impact. Therefore, it is crucial for the manufacturing facility to adopt sustainable practices, including:

- Waste Management: Proper disposal of chemical waste, including solvents, acids, and other by-products.

- Pollution Control: Implementing measures to control air emissions, water discharge, and noise pollution from the plant.

- Energy Efficiency: Adopting energy-efficient processes to minimize energy consumption and reduce the carbon footprint of the manufacturing facility.

Media Contact

Company Name: Claight Corporation

Contact Person: Peter Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au