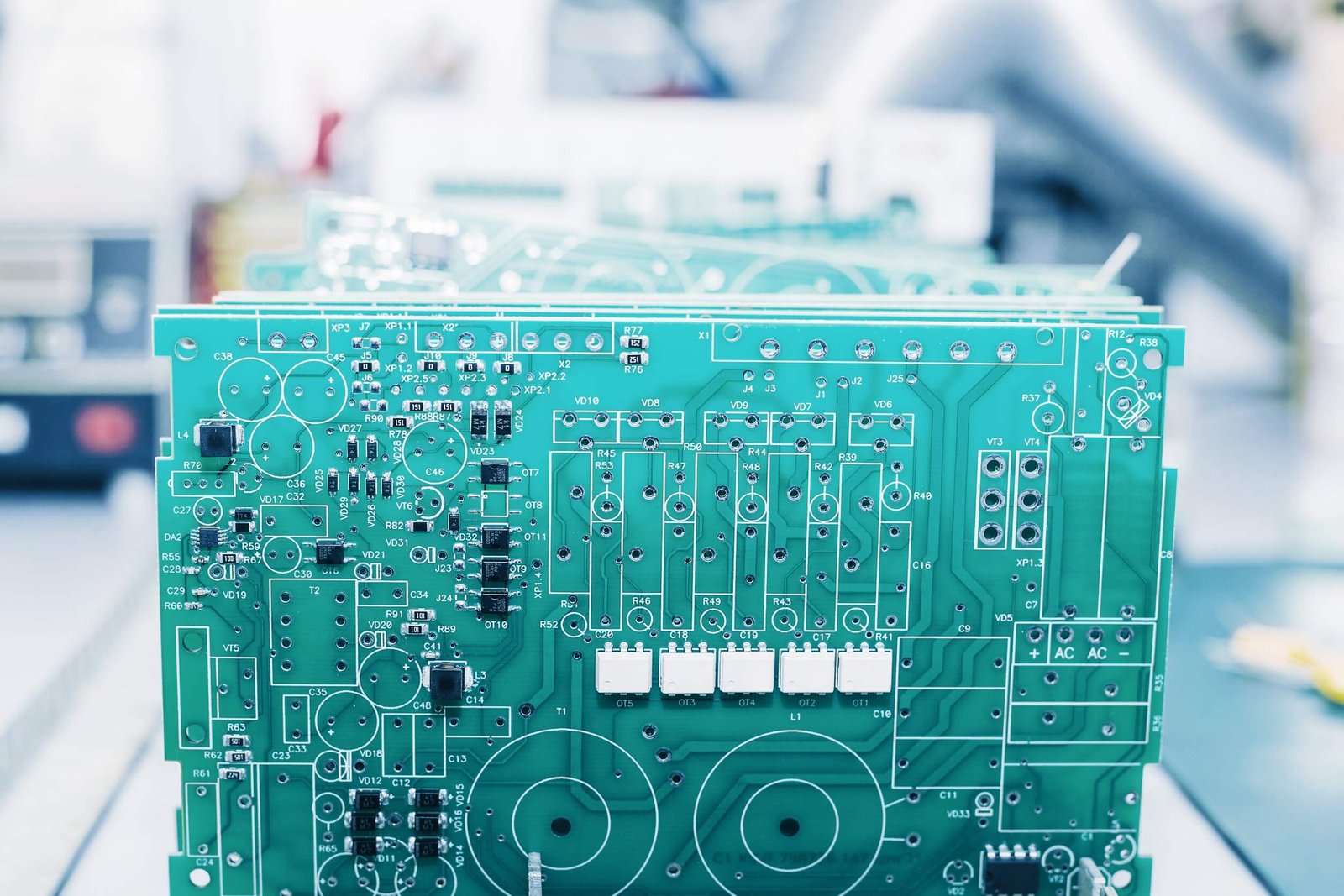

Metal core PCB is a type of Printed Circuit Board (PCB) that uses a metal coating, instead of a polymer, as the substrate for the circuit board. This makes them more durable, conductive, and heat resistant.

It is a special type of PCB that has a metal layer on its bottom side. This metal layer is covered by a dielectric material such as FR4 or BGA. The dielectric material helps to reduce the inductance of the circuit and increase its speed.

Metal core printed circuit boards or MCPCBs are used in applications that require extreme reliability and resistance to high temperatures. They can withstand up to 2000°C without degrading or melting, making them ideal for industrial environments.

The main benefit of MCPCBs is their durability. Metal cores reduce corrosion and oxidation which allows them to be used in harsh environments without compromising performance.

Benefits of a metal core PCB:

MCPCB is a technology that has been used in some of the most advanced devices on the market today, including smartphones and computers. The benefits of MCPCB are numerous and include:

- High Conductivity

Metal cores offer superior conductivity, which allows more current to flow through them than plastic core boards. This allows for better performance, as well as less power consumption.

- Improved Heat Dissipation

Metal cores allow heat to be dissipated more effectively than plastic cores do. When heat is generated, it can be dispersed through the board’s design more efficiently; this means that less heat will be trapped inside the device. In addition, metal-core PCBs do not absorb moisture from the air or moisture from liquid sources (e.g., sweat). This makes them ideal for use in high-humidity environments such as hospitals or warehouses where humidity levels are often high and it is important for boards to remain dry and protected from contaminants like bacteria and mold spores.

- Less Costly Manufacturing

Metal core printed circuit boards are typically less expensive than plastic ones because they require fewer components to manufacture; however, this does not mean that they cost less per unit sold because they still require mounting hardware.

- High-frequency performance

The metal layer helps the PCB dissipate heat more efficiently than a traditional PCB. This can be useful in high-power applications where heat is a major concern.

- Microwave interference shielding

The metal layer acts as an effective shield against microwave leakage, which can cause interference with other devices on the same board.

Summary

Metal core PCB is a type of printed circuit board that consists of an aluminum foil laminate with copper foil laminated on top of it. It provides greater performance and reliability than the traditional board, which has an epoxy resin layer.

Metal core printed circuit boards are a good choice for high frequency applications. They are used in many industries including aerospace, defense, medical, and consumer electronics.

The main benefit of using MCPCB is that it provides better heat dissipation. This allows for faster CPU speeds, more processor cores, and improved memory performance in laptops and desktop computers.