Electric motors are essential parts in various industries and applications in Pakistan. From factories to homes, electric motors are utilized in fans, siphons, blowers, transports, and more. Their productivity, reliability, and versatility make them indispensable in a great many areas, including manufacturing, agriculture, and transportation. In any case, to guarantee optimal performance and life span, regular maintenance is crucial. In this blog, we’ll examine the maintenance prerequisites and costs associated with electric motors in Pakistan, along with their advantages, importance, and various sorts to assist you with understanding the prescribed procedures for keeping these critical gadgets in top condition.

1. Understanding Electric Motors

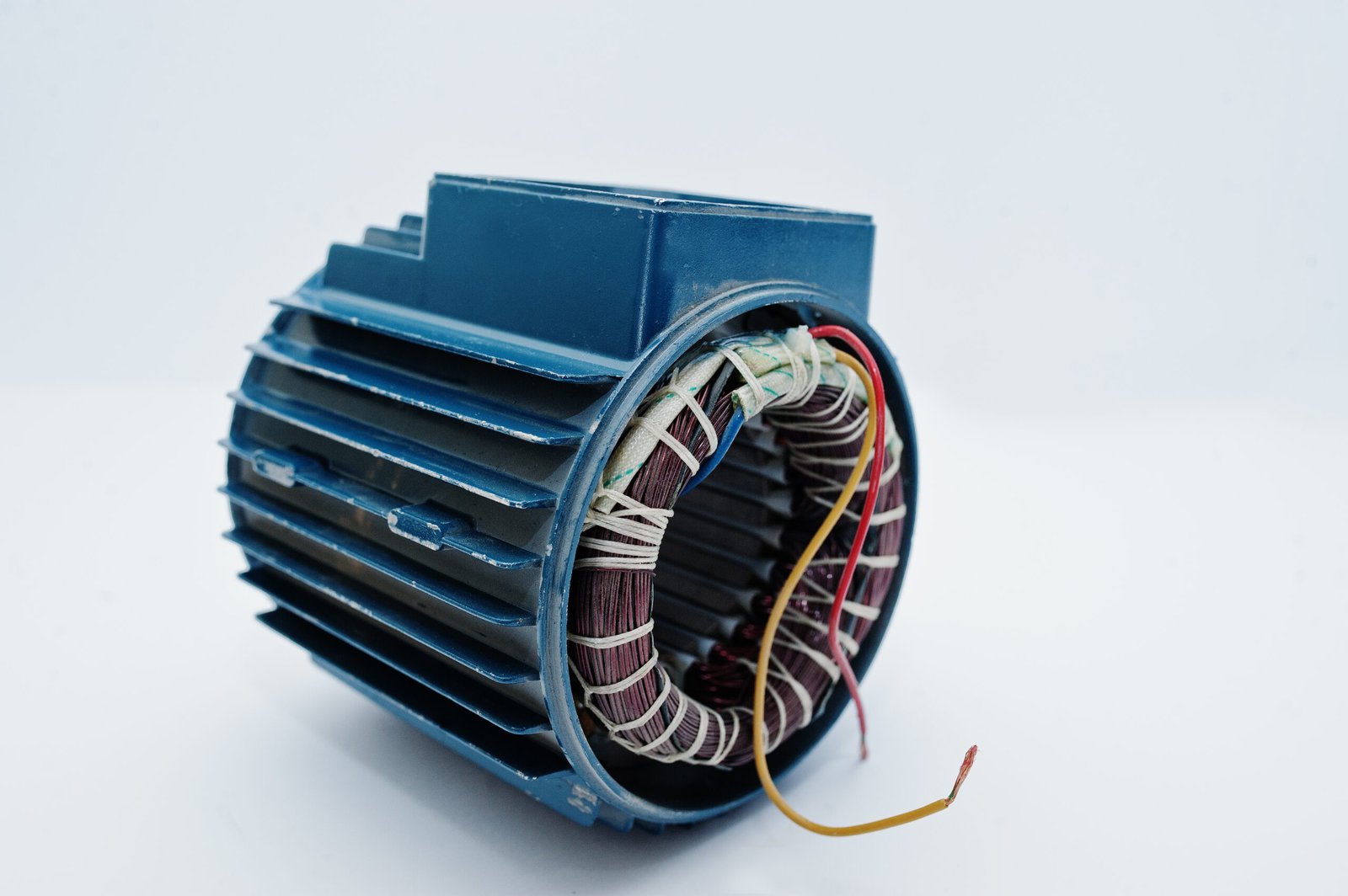

An electric engine changes over electrical energy into mechanical energy, powering various machinery and gadgets. There are various kinds of electric motors, like AC (Alternating Flow) motors, DC (Direct Flow) motors, simultaneous motors, and induction motors. Each type has its particular application and maintenance necessities. Given Pakistan’s assorted industrial landscape, these motors are broadly utilized in both small and large-scale operations.

Sorts of Electric Motors Ordinarily Utilized in Pakistan:

AC Motors: Predominantly utilized in home devices and industrial hardware.

DC Motors: Ordinarily tracked down in vehicles and portable devices.

Coordinated Motors: Known for high productivity, often utilized in situations where constant speed is required.

Induction Motors: Oftentimes utilized in heavy-obligation applications, including siphons, fans, and blowers.

2. Importance of Electric Engine Maintenance

Maintaining electric motors is essential because of multiple factors. In the first place, it broadens the engine’s lifespan, preventing startling breakdowns that could disturb operations. Second, regular maintenance enhances energy proficiency, which is critical in Pakistan, where energy assets are restricted, and blackouts are normal. By improving productivity, maintenance decreases electricity bills, making it more affordable for businesses to operate in the long haul.

Key Advantages of Regular Electric Engine Maintenance:

Increased Reliability: Forestalls surprising free times and guarantees smooth operations.

Cost Savings: Decreases repair costs and saves energy, lowering overall costs.

Enhanced Safety: Forestalls overheating and potential safety hazards.

Advanced Performance: Guarantees the engine runs at peak proficiency, minimizing energy wastage.

3. Essential Maintenance Practices for Electric Motors

Appropriate maintenance of electric motors involves both routine checks and occasional repairs. The following are a few essential practices that can help in extending the engine’s life and ensuring it works without a hitch.

A. Regular Inspection and Cleaning

Visual Inspection: Regularly look at the engine for indications of wear and tear, free associations, and consumption.

Residue and Trash Removal: Accumulated residue can deter airflow, causing overheating. Occasional cleaning is essential, especially in dusty industrial areas in Pakistan.

B. Lubrication

Motors contain bearings and other moving parts that expect lubrication to minimize grinding and wear. Inadequate lubrication can lead to premature engine failure. Notwithstanding, over-lubrication ought to also be avoided, as it can damage the engine.

Wait: electric motor prices in Pakistan can shift altogether depending on different variables, like motor sort, determinations, productivity guidelines, and brand.

C. Monitoring Temperature and Vibration

Overheating is a typical cause of engine failure. Use temperature sensors to screen the engine’s temperature. Additionally, vibration monitoring can assist with identifying issues like misalignment, free parts, or imbalances before they escalate into major issues.

D. Electrical Testing

Regularly test electrical parts like windings, insulation resistance, and voltage levels. Any inconsistency in voltage or resistance can indicate underlying issues.

4. Costs of Electric Engine Maintenance in Pakistan

Maintenance costs for electric motors in Pakistan vary depending on the engine type, usage, and explicit maintenance necessities. The following are a portion of the main cost parts:

A. Routine Maintenance Costs

Inspection and Cleaning: Basic inspection and cleaning administrations are generally affordable, costing between PKR 500 to PKR 1,500 for each meeting for smaller motors, and higher for industrial-scale motors.

Lubrication: Costs for lubricants can range from PKR 200 to PKR 2,000, depending on the engine size and kind of lubricant required.

B. Replacement Parts

Bearings: Bearing replacement can range from PKR 500 to PKR 10,000, depending on the engine size and bearing sort.

Brushes and Windings: In the case of DC motors, brushes may require regular replacement, costing between PKR 300 to PKR 2,000. Winding repair or rewinding can be costly, with costs varying from PKR 2,000 to PKR 15,000.

C. Electrical Testing

Routine electrical tests, for example, insulation resistance and winding resistance tests can cost around PKR 1,000 to PKR 3,000 for each test, depending on the engine’s intricacy.

5. Normal Challenges in Electric Engine Maintenance in Pakistan

While regular maintenance is vital, there are challenges in ensuring reliable care for electric motors in Pakistan.

A. Lack of Gifted Technicians

There’s a shortage of gifted technicians with skill in electric engine maintenance, leading to higher labor costs and some of the time inadequate servicing.

B. Restricted Access to Top notch Spare Parts

Finding great replacement parts can be troublesome, especially in far off areas. This can increase free time and maintenance costs.

C. Power Fluctuations

Regular blackouts and voltage fluctuations can put additional weight on electric motors, accelerating wear and tear.

6. The Importance of Electric Motors for Pakistan’s Economy

Electric motors play a vital job in Pakistan’s economy. They power critical areas like manufacturing, agriculture, and transportation, straightforwardly impacting efficiency and monetary development. Effective and all around maintained motors lead to energy savings, which is especially important in Pakistan’s energy-scarce climate. Moreover, diminished maintenance costs allow industries to reinvest savings in expansion and innovation, along these lines boosting overall monetary versatility.

End

Electric motors are essential to many industrial, commercial, and homegrown applications in Pakistan. Appropriate maintenance, including regular inspections, lubrication, and electrical testing, is crucial for extending engine lifespan, optimizing performance, and reducing costs. While maintenance requires an investment on schedule and assets, the advantages — ranging from energy productivity to cost savings — make it certainly worth the work. By following a preventive maintenance plan, investing in quality parts, and training gifted technicians, businesses can maximize the value and life span of their electric motors, contributing to a more sustainable and useful industrial climate in Pakistan.