In industries where equipment durability, reliability, and high performance are paramount, selecting the right type of valve can make all the difference. Knife edge gate valves have become the preferred choice in many heavy-duty sectors due to their robust design, ability to handle tough media, and excellent sealing capabilities. Industries such as mining, power generation, wastewater treatment, and manufacturing are increasingly turning to these specialized valves to meet their demanding operational needs.

This article delves into what makes knife edge gate valves so effective, their primary applications, key features, and why they are considered the ultimate solution for heavy-duty industries.

What Are Knife Edge Gate Valves?

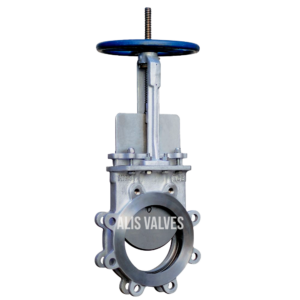

Knife edge gate valves are a type of gate valve designed to cut through thick, viscous, or fibrous media with ease. Unlike traditional gate valves, which can struggle with slurry and solid-laden fluids, knife edge gate valves are equipped with a sharp-edged gate. This design ensures that the valve can easily slice through solid particles or debris that would otherwise clog or damage standard valves.

The key feature of a knife edge gate valve is the thin, knife-like disc that allows for a clean shut-off, even in systems with slurry or dense media. This makes them particularly useful in heavy-duty applications, where handling materials like wastewater, slurry, pulp, and chemical mixtures is commonplace.

Key Features of Knife Edge Gate Valves

To understand why knife edge gate valves are the ultimate solution for heavy-duty industries, it’s important to explore their key features:

- Durable Construction Knife edge gate valves are built from robust materials like stainless steel, cast iron, and other alloys, ensuring they can withstand harsh environments and abrasive media. This construction allows them to operate in high-pressure and high-temperature conditions, making them suitable for industries such as oil and gas, mining, and power generation.

- Precision Sealing One of the major advantages of knife edge gate valves is their ability to provide a tight seal, even when dealing with challenging media like slurry, sludge, or thick fluids. This tight sealing capability reduces leakage, which is essential in industries where product loss or contamination can be costly and dangerous.

- Low Maintenance Requirements Knife edge gate valves are designed for longevity and reliability, reducing the need for frequent maintenance. Their ability to handle solids and debris without clogging or sticking minimizes downtime, which is critical for heavy-duty operations.

- Efficient Operation The sharp-edged gate enables smooth opening and closing even when the valve is dealing with dense or viscous materials. This reduces the force needed to operate the valve, making it more energy-efficient and reducing wear and tear on the system over time.

- Corrosion and Abrasion Resistance These valves are often used in highly corrosive or abrasive environments. Their ability to resist wear from exposure to chemicals, high temperatures, or abrasive materials like sand or slurry means they have a longer operational life compared to standard gate valves.

Applications of Knife Edge Gate Valves in Heavy-Duty Industries

- Mining Industry In mining operations, handling slurry, tailings, and other abrasive materials is routine. Knife edge gate valves excel in this environment because they can easily cut through solid-laden fluids, ensuring a reliable seal and minimizing maintenance downtime. Their durability is especially important when dealing with corrosive chemicals used in ore processing.

- Wastewater Treatment Wastewater treatment facilities often deal with thick sludge, fibrous materials, and solid waste. Standard valves can struggle with these materials, leading to clogs or leaks. Knife edge gate valves are designed to handle these tough conditions, providing reliable shut-off and reducing the need for frequent cleaning or repairs. This makes them an ideal choice for wastewater and sewage management applications.

- Pulp and Paper Industry The pulp and paper industry requires valves that can handle high volumes of fibrous material. Knife edge gate valves excel in these applications by ensuring smooth flow control without clogging. Their precision sealing also prevents unwanted media escape, making them a popular choice in pulp processing plants.

- Power Generation Power plants, particularly those dealing with coal, biomass, or nuclear energy, face high-pressure, high-temperature conditions. Knife edge gate valves are used in ash handling systems, slurry pipelines, and other areas where solid materials need to be effectively managed. Their resistance to wear and corrosion ensures they remain operational in these harsh environments.

- Chemical Processing In the chemical industry, valves must be able to handle highly corrosive or hazardous materials without compromising performance. Knife edge gate valves are often used in chemical processing plants because of their robust construction and ability to maintain a tight seal under harsh conditions, preventing dangerous leaks and ensuring operational safety.

Why Knife Edge Gate Valves Are the Ultimate Solution

Knife edge gate valves stand out from other industrial valves due to their ability to handle a wide range of challenging conditions. Here’s why they are the ultimate solution for heavy-duty industries:

- Enhanced Longevity Due to their construction from durable, corrosion-resistant materials, knife edge gate valves have a longer service life, reducing the total cost of ownership over time. For industries that operate in tough environments, valve longevity is crucial to maintaining profitability and efficiency.

- Cost-Effectiveness The low maintenance requirements and reliable sealing performance of knife edge gate valves reduce operational costs. These valves minimize leakage, product loss, and downtime, helping industries operate more efficiently.

- Adaptability Knife edge gate valves are versatile, used across various industries and able to manage a wide range of media types. Their adaptability makes them a go-to solution for industries with evolving or complex operational needs.

- Operational Safety In industries handling hazardous or environmentally sensitive materials, the ability to prevent leaks is critical. The precision sealing of knife edge gate valves enhances safety by minimizing the risk of exposure to harmful substances.

- Optimized Flow Control Knife edge gate valves ensure smooth flow control, even when handling thick, viscous materials. This optimized flow improves overall system performance, reducing energy consumption and enhancing productivity.

Conclusion

Knife edge gate valves have proven to be the ultimate solution for heavy-duty industries that require reliable performance in challenging environments. From mining to wastewater treatment, these valves offer durability, efficiency, and precision that make them indispensable in managing thick fluids, slurries, and solid-laden materials.

For industries seeking a cost-effective, low-maintenance valve solution, knife edge gate valves provide the perfect combination of performance and longevity, ensuring smooth operation and reduced downtime. Their ability to resist corrosion, provide a tight seal, and handle tough media makes them a top choice in some of the world’s most demanding sectors.