Computer Numerical Control (CNC) programming has transformed the landscape of manufacturing by offering an automated solution to traditional machining processes. From aerospace to automotive industries, CNC programming has become integral in producing highly accurate, efficient, and cost-effective components. This article explores what CNC programming is, how it works, its role in modern manufacturing, the types of CNC machines, and the benefits it provides to various industries.

What is CNC Programming?

CNC programming refers to the process of creating a set of instructions that control CNC machines to perform specific tasks, such as cutting, drilling, milling, and shaping materials. These instructions, typically written in languages such as G-code and M-code, direct the machine on how to move its tool or workpiece, enabling it to produce intricate, precise parts from raw materials.

Unlike traditional manual machines, where operators directly control the tool’s movement, CNC machines follow pre-programmed instructions, allowing for high-speed, repeatable production processes. CNC programming is essential in industries that require precision and consistency, and it has greatly improved productivity and efficiency.

The Role of CNC Programming in Manufacturing

CNC programming has a significant impact on various industries due to its ability to automate complex tasks and enhance production capabilities. Below are some of the key ways CNC programming is revolutionizing manufacturing:

1. Precision and Accuracy

CNC programming allows manufacturers to achieve extremely high precision levels. With the ability to create parts with micro-level tolerances, CNC machines ensure that components meet exact specifications, which is critical in industries such as aerospace, medical device manufacturing, and electronics.

The ability to program tools to move in very specific patterns and follow predetermined paths results in repeatable, consistent parts that meet stringent quality control standards.

2. Increased Efficiency

One of the most significant advantages of CNC programming is increased efficiency. CNC machines can operate continuously and perform tasks at higher speeds compared to manual operations. Additionally, CNC programming minimizes human errors, reduces machine setup times, and allows for multi-tasking operations—ultimately leading to faster production cycles.

3. Cost-Effectiveness

Although initial investments in CNC machines and programming software may seem high, they lead to long-term savings. With reduced labor costs, minimal downtime, and fewer errors in the manufacturing process, CNC programming offers cost-effective solutions for mass production. Moreover, the precision and automation help in reducing material waste, contributing to further savings.

4. Complex Part Manufacturing

CNC programming allows for the production of highly complex, intricate, and custom parts. With the ability to automate sophisticated tool paths and motions, CNC programming enables the manufacture of components with challenging geometries that would be difficult, if not impossible, to produce with traditional machining methods. This capability is especially useful in industries like aerospace, where parts often have complex shapes and tight tolerances.

The CNC Programming Process

CNC programming involves several stages to ensure that the final product is manufactured correctly. These stages include:

1. Designing the Part (CAD Modeling)

The first step in CNC programming is creating a design of the part. This is typically done using Computer-Aided Design (CAD) software. CAD models allow designers to visualize the part in 3D, which is essential for understanding the dimensions, features, and assembly requirements. Once the design is complete, it serves as the foundation for creating the CNC program.

2. Converting CAD Models into CNC Code (CAM Programming)

Once the design is finalized, the next step is to convert the CAD model into a format that can be read by the CNC machine. This is done using Computer-Aided Manufacturing (CAM) software, which generates CNC code from the 3D model. The CAM software calculates the toolpath, determining the movements the machine must make to cut the material as per the design specifications.

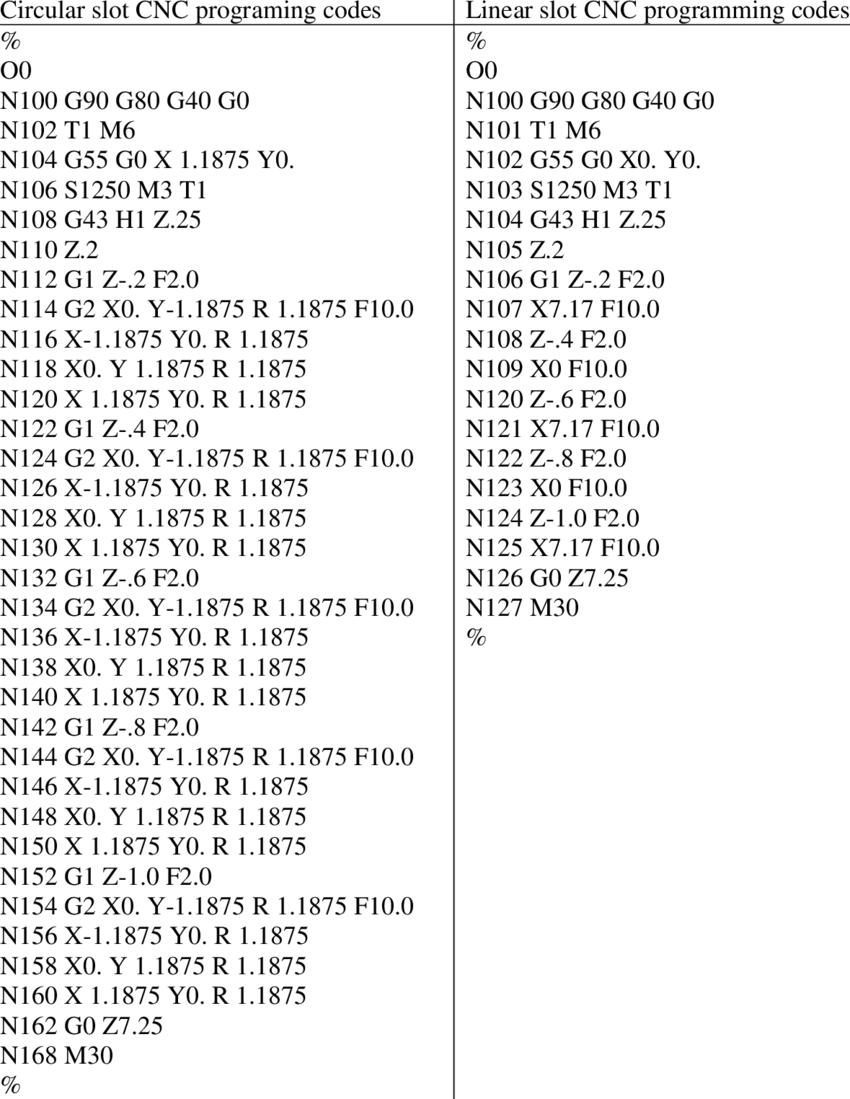

3. Writing the CNC Program (G-code and M-code)

The CNC machine reads instructions in the form of G-code and M-code. G-code provides the geometric instructions for the movement of the cutting tool, while M-code manages auxiliary machine functions like spindle control and coolant activation. The CNC programmer manually writes or automatically generates this code based on the CAD and CAM outputs.

Examples of G-code commands include:

- G0: Rapid positioning (moving to a specified location without cutting)

- G1: Linear interpolation (cutting along a straight line)

- G2/G3: Circular interpolation (cutting along an arc, clockwise or counterclockwise)

M-code examples include:

- M3: Turn on spindle (clockwise rotation)

- M5: Stop spindle

- M8: Activate coolant flow

4. Simulation and Verification

Before the CNC machine begins manufacturing the part, the CNC program is often simulated to detect potential errors, such as tool collisions or incorrect movements. This step ensures that the program runs as intended and the machine will follow the correct toolpath without damaging the material or equipment.

Many modern CAM software packages provide simulation tools, allowing programmers to visualize and adjust the toolpath in a virtual environment before the program is run on the machine.

5. Execution on the CNC Machine

Once the program is verified, it is loaded into the CNC machine, and production begins. The CNC machine will follow the instructions provided in the program, performing all the necessary tasks, such as cutting, drilling, and milling, to create the finished part.

During production, operators monitor the machine’s performance, making any adjustments or corrections as needed.

Types of CNC Machines

CNC machines come in various types, each designed to perform specific tasks. Some of the most common types of CNC machines include:

1. CNC Milling Machines

CNC milling machines are used to remove material from a workpiece by rotating a cutting tool. They are highly versatile and can perform tasks like drilling, tapping, and surface milling. CNC mills are used in industries like aerospace and automotive to produce intricate parts.

2. CNC Lathes

CNC lathes are designed for turning operations. They rotate the workpiece against a stationary cutting tool to create cylindrical shapes. CNC lathes are widely used in manufacturing components such as shafts, bolts, and bushings.

3. CNC Routers

CNC routers are typically used in woodworking, metalworking, and plastics manufacturing. They are designed for high-speed cutting of large materials and can handle a wide range of cutting tasks, including engraving and shaping.

4. CNC EDM (Electrical Discharge Machines)

CNC EDM machines are used for precision machining of hard metals, particularly when the material cannot be easily cut with traditional tools. They are commonly used for making molds and die-cuts.

Benefits of CNC Programming

CNC programming provides numerous advantages to manufacturers, making it a preferred method of machining for many industries:

1. Enhanced Precision and Consistency

CNC programming ensures that each part is made to exact specifications with minimal deviation, even in high-volume production. This results in highly consistent, repeatable parts that meet quality standards.

2. Increased Flexibility

CNC programming allows for quick changes to be made in the design and production process. If a modification to the part is needed, the program can be easily updated, and the machine can begin producing the new design with minimal delay.

3. Reduced Labor Costs

CNC programming reduces the need for skilled labor during the production process. Once the program is set, the machine can operate autonomously, requiring minimal supervision and reducing the reliance on manual operators.

4. Faster Production

CNC machines operate faster than manual machines, and their automation ensures that the machine can work around the clock without fatigue. This increases overall production rates, reducing lead times for parts and assemblies.

5. Improved Safety

CNC machines are equipped with safety features, such as automatic shutdowns and protective enclosures, that protect workers from potential hazards. By reducing direct human involvement, CNC programming helps minimize the risk of accidents.

The Future of CNC Programming

As technology continues to evolve, the future of CNC programming looks promising. With advancements in artificial intelligence (AI) and machine learning, CNC programming may become even more automated. AI systems could help optimize toolpaths and improve manufacturing efficiency by predicting wear and tear on tools or detecting potential failures before they occur.

Additionally, the integration of additive manufacturing (3D printing) and CNC machining could lead to hybrid machines capable of both subtractive and additive manufacturing processes, offering even greater flexibility and versatility.

Conclusion

CNC programming is a vital component of modern manufacturing, enabling companies to produce highly accurate, efficient, and cost-effective components. Its role in various industries—from automotive and aerospace to medical devices—cannot be overstated. As technology advances, CNC programming will continue to evolve, allowing for even greater precision, automation, and efficiency in manufacturing processes worldwide.