Introduction:

The Role of VFDs in Industrial Efficiency and Control

. Begin with a hook on how industries today demand efficiency, energy savings, and precise motor control.

. Introduce Variable Frequency Drives (VFDs) as a solution that enables motor speed control, energy efficiency, and system optimization across various applications.

. Briefly outline the key points covered in the article: the advantages of VFDs, their impact on different sectors, and tips for selecting the right VFD.

- What is a Variable Frequency Drive (VFD)?

. 1.1 Definition and Purpose of VFDs

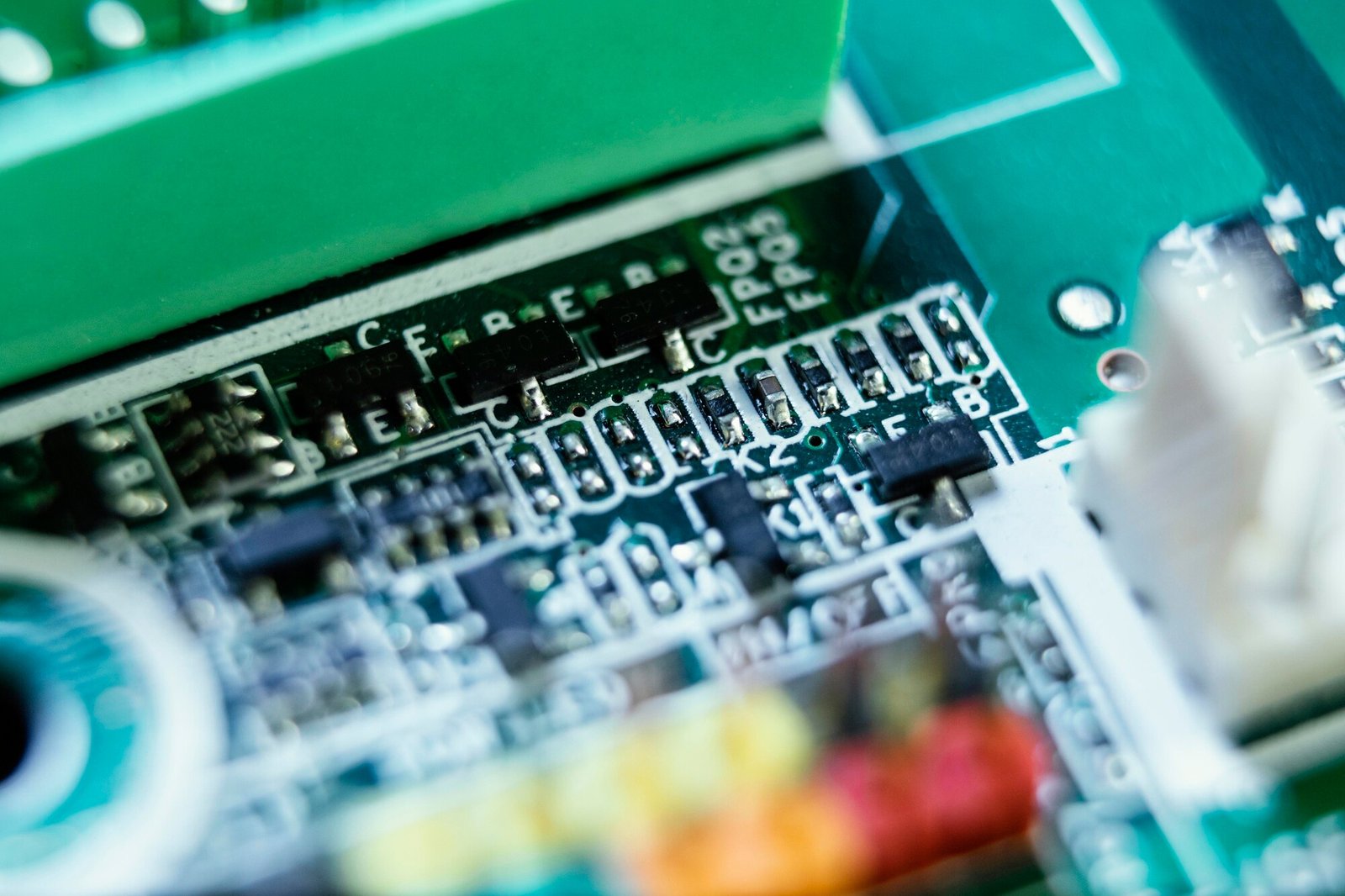

. Explain VFDs as electronic devices that control the speed and torque of motors by adjusting the frequency and voltage supplied.

. 1.2 Basic Working Principle of VFDs

. Briefly cover how VFDs use Pulse Width Modulation (PWM) to control the motor’s speed and power usage.

. 1.3 Common Applications of VFDs

. Mention applications across sectors like HVAC systems, manufacturing, pumps, fans, conveyors, and other motor-driven processes.

- Key Advantages of Choosing Variable Frequency Drives (VFDs)

. 2.1 Energy Efficiency and Cost Savings

. Explanation of Energy Savings: VFDs adjust the motor speed based on load demand, reducing unnecessary energy consumption.

. Reduced Operating Costs: Show how lower energy usage leads to significant cost savings over time, especially for energy-intensive industries like manufacturing.

. Example Calculation of Savings: Provide a simple calculation or example of how VFDs can save energy and reduce expenses.

. 2.2 Improved Motor Control and Precision

. Precision in Speed and Torque Control: Discuss how VFDs allow precise control over motor speed, optimizing performance for specific tasks.

. Applications Requiring Precision: Mention industries or tasks where speed precision is essential, such as conveyor belts, drilling, and mixing processes.

. 2.3 Enhanced Process Control and Productivity

. Optimization of Workflow: Explain how VFDs allow for better control over the entire production line, resulting in smoother operations.

. Increased Equipment Lifespan: Discuss how controlled speed prevents mechanical stress and reduces wear, extending the life of motors and machinery.

Attention: variable frequency drive VFDS empowers exact control of engine speed and force, considering better cycle the board and further developed item quality.

. 2.4 Reduced Mechanical Stress and Maintenance Costs

. Lower Wear on Motors: Describe how VFDs reduce the sudden shock of starting motors at full power, lowering the wear and tear on components.

. Extended Maintenance Intervals: Highlight how smoother operation and reduced stress mean less frequent maintenance and fewer unscheduled repairs.

. 2.5 Enhanced System Flexibility and Scalability

. Adapting to Load Variability: Describe how VFDs enable flexibility to adjust motor speed based on varying load demands, making them ideal for industries with changing production rates.

. Future-Readiness and Expansion: Explain how VFDs offer scalability, making them suitable for industries planning to expand production or upgrade equipment.

. 2.6 Reduction of Power Demand Peaks

. Avoidance of Power Surges: Explain how VFDs prevent motors from drawing maximum power at startup, which lowers peak demand charges from utility companies.

. Impact on Power Bills: Discuss how avoiding power surges translates to reduced electricity bills, especially for industries with high-powered machinery.

. 2.7 Environmental Benefits

. Lower Carbon Footprint: Highlight how energy-efficient VFDs contribute to reduced greenhouse gas emissions.

. Sustainability Goals: Emphasize how VFDs align with sustainability goals, making them an attractive choice for companies aiming to reduce their environmental impact.

- Sector-Specific Advantages of Variable Frequency Drives

. 3.1 Manufacturing and Industrial Production

. Describe how VFDs enhance precision and efficiency in processes like milling, grinding, and assembly lines.

. Discuss the reduction in production downtime due to optimized motor control and reduced equipment failure.

. 3.2 HVAC Systems

. Explain how VFDs improve heating, ventilation, and air conditioning systems by modulating fan and pump speeds based on building occupancy and climate conditions.

. Mention the significant energy savings and improved comfort levels VFDs bring to commercial and industrial HVAC systems.

. 3.3 Water and Wastewater Treatment

. Discuss how VFDs control pump speed in water treatment facilities, ensuring steady water flow and pressure without unnecessary power consumption.

. Describe the reduced maintenance costs and energy savings in water treatment applications due to VFD implementation.

- Practical Tips for Selecting the Right Variable Frequency Drive

. 4.1 Evaluate Motor Requirements

. Explain how to match the VFD to the motor’s power rating, load, and application to ensure compatibility and performance.

. Discuss considerations like torque requirements and application-specific needs (e.g., constant torque for conveyors vs. variable torque for pumps).

. 4.2 Consider Environmental Factors

. Mention factors like temperature, humidity, and potential exposure to dust or chemicals, which can impact VFD performance.

. Recommend VFDs with protective features or enclosures for harsh environments.

. 4.3 Look for Built-in Safety Features

. Describe essential safety features, such as overload protection, automatic shutdown, and fault alarms, to ensure safe operation.

. Mention how these features not only enhance safety but also reduce the risk of damage to the motor and VFD.

- The Future of Variable Frequency Drives: Trends and Innovations

. 5.1 Advances in VFD Technology

. Mention the latest innovations, like compact designs, improved energy efficiency, and intelligent VFDs with AI-driven diagnostics and predictive maintenance.

. Discuss how these developments are making VFDs more efficient and accessible to a broader range of industries.

. 5.2 IoT-Enabled and Smart VFDs

. Explain how smart VFDs connected to the Internet of Things (IoT) allow for real-time monitoring, remote control, and performance optimization.

. Discuss how IoT integration is helping industries streamline operations and improve maintenance through data-driven insights.

Conclusion:

Maximizing Operational Efficiency and Savings with Variable Frequency Drives

. Summarize the numerous benefits of VFDs, from energy savings and precise motor control to reduced maintenance and environmental impact.

. Reinforce the idea that VFDs are a wise investment for companies looking to reduce costs, increase efficiency, and enhance process control.

. End with a call to action, encouraging readers to explore the right VFD options for their applications and take advantage of the energy and cost savings that VFDs can offer.