Introduction

Reinforcement bars, commonly referred to as rebars, are vital components in the construction industry. These steel bars are embedded within concrete structures to provide tensile strength and improve overall structural integrity. With a wide range of dimensions, grades, and varieties available, selecting the appropriate rebar for a specific application can be a complex task. This article will examine the key features of rebar, including its dimensions, grades, and different types to assist you in making informed decisions – mur.

Understanding Rebar Dimensions

Rebar dimensions are standardized to ensure consistency and compatibility in construction projects. The primary dimensions of a rebar include:

Diameter: Measured in millimeters or inches, the diameter determines the cross-sectional area of the rebar and its ability to resist tensile forces.

Length: Rebars are available in various standard lengths, although custom lengths can be ordered to suit specific project requirements.

Shape: While most rebars are round in shape, other shapes like deformed and square bars are also available for specific applications.

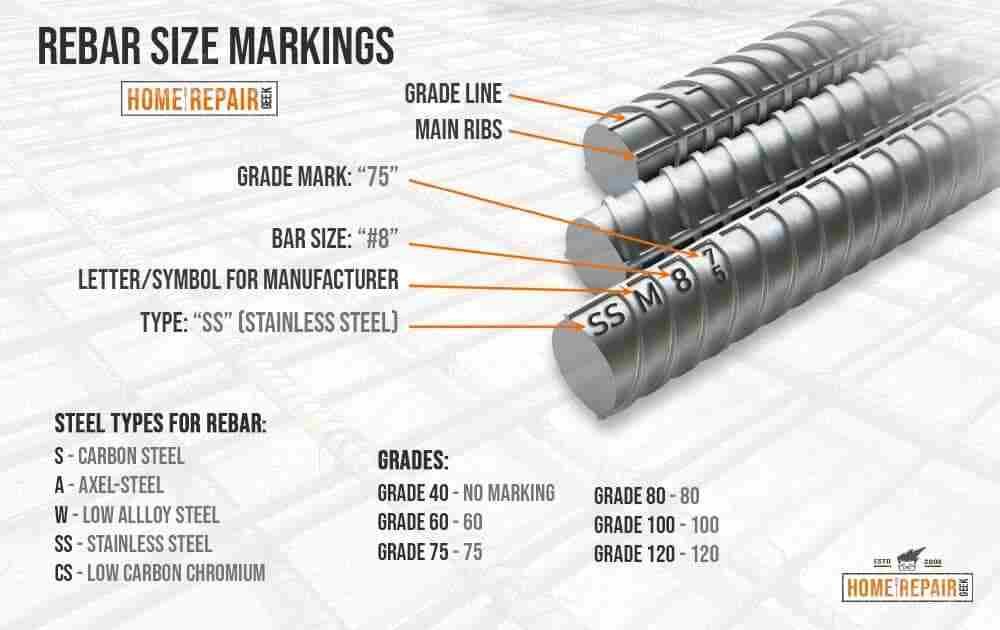

Rebar Grades

The grade of a rebar refers to its strength and ductility. Different grades of rebar are produced by varying the chemical composition and manufacturing process. Higher-grade rebars generally have higher tensile strength and are suitable for applications that require greater load-bearing capacity. Common rebar grades include:

Grade 40: A widely used grade with moderate strength.

Grade 60: Offers higher strength than Grade 40 and is suitable for more demanding applications.

Grade 75: Provides the highest strength among commonly available grades and is used in structures subjected to extreme loads.

Varieties of Rebar

Rebars are available in various types to cater to different construction needs. Some common varieties include:

Deformed rebars: These rebars have a ribbed surface that enhances the bond between the rebar and the concrete, improving the overall strength of the structure.

Epoxy-coated rebars: Coated with epoxy resin, these rebars offer superior corrosion resistance and are ideal for use in harsh environments or applications where corrosion is a concern.

Black rebars: These are the most common type of rebar and are not coated. They are typically used in interior applications where corrosion is not a major issue.

Stainless steel rebars: Made from stainless steel, these rebars offer excellent corrosion resistance and are used in applications that require high durability and aesthetic appeal.

Factors Affecting Rebar Selection

Several factors influence the selection of rebar for a particular construction project, including:

Structural loads: The magnitude and type of loads that the structure will be subjected to will determine the required strength and quantity of rebars.

Environmental conditions: Factors such as exposure to moisture, chemicals, and temperature extremes will influence the choice of rebar grade and coating.

Construction codes and standards: Building codes and industry standards provide guidelines for the selection and use of rebars in different types of structures.

Cost considerations: The cost of rebars can vary significantly based on their grade, diameter, and coating.

Conclusion

By understanding the various dimensions, grades, and varieties of rebars, engineers and contractors can make informed decisions to select the most suitable rebar for their specific project requirements.

Keywords: rebar dimensions, rebar grades, rebar types, reinforcement bars, steel bars, construction, concrete, structural engineering, engineering, civil engineering, building codes, tensile strength, ductility, epoxy-coated rebar, deformed rebar, black rebar, stainless steel rebar.

Visit: hafas – tokohasil.com