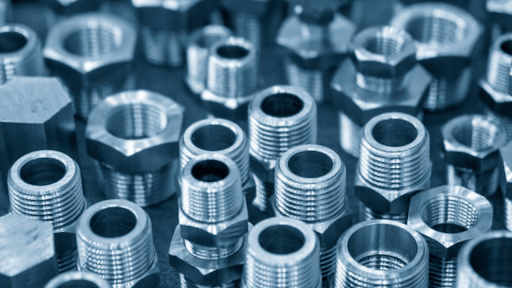

Are you looking for reliable and cost-effective solutions for connecting pipes, valves, and other components in fluid handling systems? Threaded pipe fittings are the answer!

These pipe fittings are used in various industries for their ability to connect pipes without the need for complex wielding.

They offer unmatched versatility and ease of installation, so they are considered reliable in harsh conditions.

So, are you curious about their applications? Let’s dive into the uses of these fittings in various industries.

1. Plumbing Systems

One of the most common applications of these fittings is in residential and commercial plumbing systems. These fittings are used to connect water supply lines, drainage systems, and other plumbing components. Their ease of installation and compatibility with different pipe materials make them ideal for quickly establishing secure connections. Whether it’s joining copper, steel, or PVC pipes, threaded fittings provide a reliable solution for plumbers looking to avoid complex installations.

In plumbing, pipe fittings such as couplings, elbows, and tees are commonly used to manage the direction and flow of water within the system. They also make repairs or adjustments to plumbing systems easier, as these fittings can be removed and replaced without disturbing the entire network.

2. Oil and Gas Industry

The oil and gas industry relies heavily on these pipe fittings for various applications, including fluid and gas transportation. The durability of these fittings ensures they can withstand high pressures and harsh environments often encountered in the field. Threaded fittings provide secure and leak-proof connections in pipelines, processing plants, and drilling operations, ensuring safety and efficiency.

In this sector, materials like stainless steel are frequently used for these fittings due to their resistance to corrosion from oil, gas, and other chemicals. Stainless steel fittings also maintain their strength at high temperatures, which is critical in the demanding conditions of oil and gas operations.

3. Chemical Processing

They are indispensable in chemical processing plants, where the transportation of hazardous and corrosive substances is a daily occurrence. These plants use various fluids and chemicals that require specialized piping systems to avoid leaks and contamination. Threaded fittings made of durable materials like stainless steel or alloy metals are preferred in these settings because they resist corrosion, chemical damage, and high pressure.

For chemical processing applications, threaded fittings such as reducers, couplings, and unions are often used to adjust the size of the pipe, redirect fluid flow, or disconnect sections of the system for maintenance. Their ability to create secure, leak-free connections is crucial for maintaining safety in these potentially hazardous environments.

4. Water Distribution Systems

They play an essential role in water distribution systems, both for industrial and residential use. These systems need reliable fittings to connect pipes and valves that handle the flow of water throughout large facilities or city infrastructures. They ensure that water is transported efficiently without the risk of leaks or contamination.

In water distribution, fittings such as threaded elbows, flanges, and couplings are often used to connect pipes over long distances or in confined spaces. These fittings provide the necessary flexibility to manage the flow of water while ensuring a long-lasting, leak-resistant connection.

5. Food and Beverage Industry

The food and beverage industry also makes extensive use of these pipe fittings, especially stainless steel fittings, to ensure hygienic and safe fluid handling. In food processing plants, these fittings connect pipes that carry water, steam, and other fluids used in the production process. These fittings are critical in maintaining cleanliness and preventing contamination, as they are resistant to corrosion and easy to clean.

Stainless steel fittings, in particular, are highly favored in this industry for their durability, hygiene, and ability to withstand high temperatures. They are used in everything from water supply lines to steam and processing pipelines, ensuring the safe and efficient transfer of fluids in food production.

6. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems also rely on these fittings to connect pipes that carry refrigerants and other fluids used in the regulation of indoor climate. These systems require secure, leak-free connections to function properly, and threaded fittings provide a simple and effective solution for joining different sections of the system.

These fittings, such as unions and couplings, allow for easy maintenance and repairs in HVAC systems. These fittings can be disconnected and reassembled without disturbing the entire system, making them ideal for large HVAC installations in commercial and industrial settings.

7. Stainless Steel Threaded Pipe Fittings for High-Performance Applications

When it comes to more demanding environments, stainless steel fittings stand out for their superior performance. These fittings are constructed from stainless steel grades such as 304 and 316, which are known for their resistance to rust, corrosion, and chemical damage. This makes them ideal for industries like chemical processing, food and beverage, and oil and gas, where durability and hygiene are critical.

In addition to their corrosion resistance, stainless steel fittings are able to withstand high temperatures and pressures, making them suitable for high-performance applications in both industrial and commercial settings. These fittings come in various configurations, such as threaded reducers, hose barbs, and nipples, allowing for flexible and secure connections in fluid handling systems.

8. Versatility Across Industries

Stainless steel threaded fittings are versatile and used in a wide range of industries beyond those mentioned. From fire protection systems to marine environments, their ability to create strong, leak-resistant connections in harsh conditions makes them indispensable. Their robust construction ensures long-lasting performance, reducing the need for frequent replacements or repairs.

Conclusion

Stainless Steel threaded pipe fittings, especially stainless steel ones, are essential components in a variety of industries. Their versatility, durability, and ability to create secure, leak-free connections make them invaluable in settings ranging from residential plumbing to chemical processing and oil and gas industries. As industries continue to demand more reliable and efficient fluid handling systems, these pipe fittings will remain a crucial element in ensuring the smooth operation of these systems.